+86-18112348562

Please Choose Your Language

Views: 50 Author: Site Editor Publish Time: 2024-08-16 Origin: Site

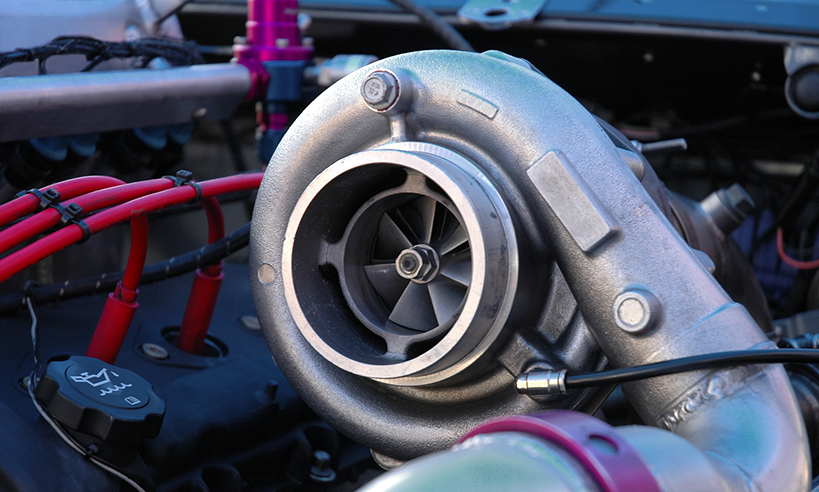

Exhaust gas turbocharger is a device that can significantly increase the engine power without changing the structure of the engine system. Theoretically, we can increase the power of the original self-priming engine by more than 30%. As a matter of fact, the technical enterprise of turbocharger has been developed very mature now, and as long as it is used and maintained properly, it can be close to the life of the engine. However, in the use and management of turbocharger process, if not used correctly, improper maintenance, often prone to a variety of failures, the following and we share the turbocharger four common failures and solutions.

abnormal oil consumption, but the engine power does not decline, smoke color is normal.

oil leakage.

1. Check the external environment of the working engine for abnormal oil leakage, especially the inlet and return oil pipes of the supercharger. If there is any leakage problem, it should be tightened in time.

2. Open the exhaust port at the turbocharger turbine end and check for oil. If there is oil, it can be inferred that the turbine end oil seal ring is damaged and needs to be replaced.

Abnormal oil consumption, engine power does not decline, exhaust blue smoke.

compressor oil leakage, oil through the turbocharger, engine intake pipe combustion chamber combustion. The supercharger oil return pipe is not smooth, the oil in the intermediate bearing at the accumulation of excessive waste, along the rotor shaft into the compressor, through the impeller. The oil seal at the compressor end of the supercharger is damaged, and the oil leaks into the compressor impeller.

Open the outlet at the pressurizer end of the supercharger and check to see if there are any traces of oil inside the outlet pipe wall. If there is, check to see if the supercharger oil return line is working properly. If it is not smooth, we will clean the oil line.

If the supercharger oil return line is smooth compressor end oil seal is damaged, you need to remove the compressor end oil seal and replace it.

Engine power significantly lower, increased fuel consumption, exhaust blue smoke

On the one hand, it will increase the gap between the engine piston ring and the cylinder liner, resulting in a poor sealing system, the engine output as the power continues to decline, the oil overflow, into the combustion chamber from the gap in the combustion, exhaust blue smoke. On the other hand, the air intake channel in front of the supercharger is not smooth, resulting in excessive vacuum at the pressurizer end of the supercharger. Oil flows into the pressurizer impeller from the middle of the supercharger and enters the combustion chamber with the compressed air. At this time, the turbocharger speed drops, the engine air intake is obviously insufficient, will show a decline in power and discharge of blue smoke.

Check whether there are oil traces on the outlet end of the supercharger compressor and pipe wall. If there are obvious oil stains, then we will check whether the intake pipe system before the supercharger is flattened and whether the air filter element is dirty. Severe cases require prompt replacement of the flattened intake tube design or replacement of the ambient air filter element.

If there are no visible oil stains on the outlet end wall of the pressurizer, then it can be deduced that the piston rings are not sealing properly and the engine will need to be disassembled to replace the piston rings or cylinder liner.

Engine power decreases significantly, and the supercharger has a strange sound. Failure causes: supercharger rotor and shell friction metal friction sound, may be supercharger bearings or thrust bearings caused by excessive wear. Supercharger compressor air intake system interface leakage, there is an abnormal air flow sound, the actual engine air intake is insufficient, gasoline combustion utilization is not in full play, resulting in black smoke and a constant decline in power.

In case of metal friction, dismantle the supercharger and observe the wear of the rotor, bearing and thrust bearing, and replace the rotor, bearing and thrust bearing if they are seriously worn.

If airflow sound is present, then connection tubes need to be resealed and tightened.

Oil leakage from both ends or one end of the supercharger is one of the most common failures in use. Theoretically speaking, the normal pressure into the intermediate oil, after passing through the bearing work surface, the oil pressure has become zero, just by gravity naturally flow downward back to the generator sump. And in the normal operating condition of the supercharger at both ends of the impeller at the back of the wheel there is a certain amount of gas pressure, so the oil is not from the low-pressure area to the high-pressure area of the flow. The main function of the sealing ring is to seal the gas leakage from the pressurizer and turbine housing to the intermediate oil chamber, and only under special circumstances, it plays the role of sealing the oil. Despite this, improper use can cause oil leakage from the ends of the supercharger under the following conditions

a. long-term idling of the diesel engine. Engine idling for a long time, the supercharger turbocharger and impeller at the back of the wheel will produce a certain amount of negative pressure, which leads to the intermediate body of oil leakage to the outside, this is the experts many times in the test bench on the special test results, so the engine should be avoided for a long time idling.

b. Poor oil return. In use, such as due to the oil return pipeline deformation or blockage, resulting in poor oil return, the oil pressure in the intermediate body is too high, the compressor oil along the rotor axial flow at both ends of the extrusion of the seal ring resulting in oil leakage. Therefore, we should always check whether the oil return pipeline is smooth, to ensure that the oil can normally flow back to the oil sump.

C. engine crankcase pressure is too high. Crankcase exhaust gas pressure exceeds the specified value, will make the supercharger oil return pipeline pressure increases, the return oil is not smooth and caused by sealing ring oil leakage. Should always check the crankcase ventilation status, as well as the lower exhaust pipeline is smooth. Diesel engines should pay extra attention to whether the oil and gas separator is working properly, in order to prevent the mixed gas in the crankcase from being pumped into the pressurizer and cylinder along the exhaust pipe, resulting in the phenomenon of diesel engine oil burning.

d. air filter cartridge will be too much dust accumulation and blockage, which leads to the negative pressure of the pressurized air intake is too high, the impeller wheel back will appear due to the negative pressure is too high caused by the sealing ring leakage of oil, so we should regularly check the maintenance of the air filter, so that the cartridge is not blocked, do not break through, and to maintain a normal state of the air supply.

e. Seal ring wear or failure. Long-term non-replacement of oil, so that too many impurities in the oil to play the role of abrasive material, resulting in increased wear and tear of the sealing ring, thinning, and gradually lose the sealing gas, oil sealing effect and lead to oil leakage. The so-called impurities refers to the oil has more than 0.02mm of foreign particles, these impurity particles can be random oil flow into the bearing and shaft oil film and sealing ring, serious abrasion of rotating parts, aggravate the wear and tear of the parts of the failure.

Floating bearing wear is one of the most common faults causing oil leakage of the supercharger, after the occurrence of such faults, the clearance between the bearing and the shaft is too large, the oil film is destabilized, the bearing capacity decreases, the rotor shaft system vibration increases, and the dynamic balance is destroyed. Excessive radius of rotation so that the two ends of the seal damage, in serious cases may make the whole supercharger destroyed.

a. Failure to use pressurized engine oil that meets the requirements. After the engine is pressurized, its thermal load and mechanical load increase greatly, and the temperature of the working condition is very high, which makes the temperature of the oil rise, the viscosity decreases, and the bearing capacity decreases. The speed of the supercharger is higher than that of the diesel engine nearly 20 times, so the temperature at the supercharger bearing is much higher than that at the crankshaft of the diesel engine. This requires the oil to have a higher viscosity, can withstand the load of high-speed rotor and higher temperatures, but also has a better dispersion, oxidation resistance and wear resistance, and ordinary oil is difficult to achieve this requirement. Booster oil is a kind of multigrade oil compounded with many kinds of additives on the basis of common engine oil. It has excellent dispersion, oxidation resistance, corrosion resistance and abrasion resistance, so it is necessary to use booster oil correctly according to the instructions of the manual.

b. the oil cleanliness is too poor. Oil contains too many impurities will accelerate the wear of bearings and shafts, often found in the maintenance of diesel generator oil sump in the oil black, dilute, and even black mud, such oil if you continue to use the bearing will undoubtedly make the bearing in a short time due to wear and tear scrapped.

C. lack of oil dry grinding. Supercharger oil is from the engine oil pump, if the oil pump is not working properly, resulting in insufficient oil supply or oil pressure is too low, as well as into the oil pipeline deformation, obstruction, cracks and other phenomena leading to insufficient oil supply, can make the supercharger bearings and shafts, due to poor lubrication and damage. Often found in the maintenance of bearings and shafts have obvious traces of dry friction, serious cases will see the phenomenon of burning into the blue. So should always check the oil pipeline, problems in time to exclude. Supercharger oil inlet pressure should be greater than 0.2MPa in order to ensure the oil supply and bearings and other rotating parts of the normal lubrication. In addition, when checking the supercharger rotor, if the axial clearance is too large, it indicates that the thrust bearing is too worn. If the radial clearance is too large, it indicates that the floating bearing is too worn.

a. the exhaust pipe into the metal. Supercharger in normal high-speed operation, if the engine exhaust pipe discharge nuts, screws and other metal objects, will inevitably cause damage to the turbine blades, and in serious cases can also be broken turbine shell. The same pressurized impeller blade encountered this situation will also be damaged, if the impeller blade is damaged, then the rotor's dynamic balance is immediately destroyed, the supercharger rotor shaft system vibration intensified, supercharging equipment can not continue to use, need to be immediately sent to the maintenance department, replace the new supercharger. In use, if you hear a different response immediately stop and check to prevent the falling compressor blade debris into the cylinder of the diesel generator, resulting in serious accidents.

b. did not use the air filter to meet the requirements. In the desert areas or harsh operating environments in the use of pressurized diesel generators, fine sand and dust through the air filter or pipeline gap into the supercharger, can lead to uniform wear and tear of the supercharger impeller blades at the air inlet, so that the supercharger pressurization effect is reduced, and in severe cases, can destroy the balance of the rotor, so it should be often on the air filter inspection and maintenance, and timely replacement of the filter element, in order to minimize the occurrence of such failures.

C. not timely removal of oil sludge. After long-term use of the supercharger, the dust in the air and oil mist will be formed into oil sludge, gradually gathered in the channel of the supercharger shell inlet, so that the impeller and the shell without clearance, or blade and the supercharger shell contact and friction, caused by the vibration of the supercharger rotor shaft system, exacerbating the wear and tear of the shaft system. Therefore, it should be frequently checked to remove the oil sludge in time.

d. exhaust gas temperature is too high. Due to the supercharger diesel generator fuel system failure, such as oil supply delay, oil supply is too large, injector drip or exhaust door leakage and other phenomena, can lead to exhaust gas temperature is too high, and then make the turbine inlet at the blade burn deformation. Excessive exhaust temperature can also make the turbine end seal oil carbonization, as well as turbine end bearings at the local overheating (check the pressure end bearings are normal while the turbine end bearings burned blue or black), resulting in premature failure of the seals and bearings.

The supercharger in the rotation of the noise is too large, there is a metal impact or friction sound, accompanied by strong vibration in serious cases.

a. the exhaust pipe between the engine and the supercharger is not sealed. Check whether the air filter is blocked, the pressurized air inlet pipe, and casing and diesel exhaust system whether there is a foreign body, the engine inlet and exhaust pipe to whether it is loose, according to the situation for cleaning or fastening.

b, impeller deformation, impeller and shell touching, the work of the gas movement changes make the supercharger strong vibration and produce high frequency noise. If the noise obviously shows metal friction sound, should check whether the supercharger lubrication is good, whether the bearing is loose, whether the blade is deformed, whether the impeller and shell phase friction, radial and axial clearance is over the limit, if necessary, decomposition inspection, replacement of damaged parts.

C. poor lubrication of floating bearings. If the supercharger needle vibration is strong, it is due to the rotor shaft assembly imbalance or floating bearing damage, should decompose the supercharger, check whether the internal parts of the foreign body or damage, and replace the damaged parts as appropriate.

d. rotor shaft serious wear, floating bearing clearance is too large, turbine blade damage, bearing damage, turbine rotor carbon deposits, so that the rotor assembly dynamic balance has been damaged. If the noise is a periodic noise may be caused by oil sludge and dust deposits, should be cleaned up impeller, turbine shell in the excessive thickness of carbon.

Due to the supercharger engine fuel system failure, such as oil supply delay, excessive oil supply or exhaust valve leakage and other phenomena, can lead to exhaust gas temperature is too high, and then make the turbine inlet at the blade burn deformation. Excessive exhaust temperature can also cause charring of the oil at the turbine end seal and localized overheating at the turbine end bearing, resulting in premature seal and bearing failure. Bypass valve actuator assembly pressure setting and calibration is performed at a specialized setting/inspection facility and cannot be changed by the customer or other personnel. Failure to do so can also cause high exhaust gas temperatures or engine weakness.

Because of the high precision of the turbocharger rotor bearings and the strict requirements of the working environment during maintenance and installation, the supercharger should be repaired at a designated service station when it is malfunctioned or damaged. In short, the user must strictly in accordance with the requirements of the instruction manual for the correct operation, as far as possible to play the three major roles of lubricating oil (lubrication, decontamination, cooling), try to avoid man-made, unnecessary failures and make the supercharger damage and scrap, so as to ensure that the supercharger should be the service life.

Case Study-How Fleets Saved Costs by Upgrading To AlfredTurbo Truck Turbochargers

5 Signs Your Truck Turbocharger Needs Replacement Immediately

OEM Vs Aftermarket Truck Turbochargers Which One Should You Choose

The Role of Turbochargers in Reducing Emissions for Diesel Trucks

Complete Buyer’s Guide To Heavy Truck Turbochargers (2025 Edition)

Top 10 Factors To Consider When Choosing A Truck Turbocharger

How Turbochargers Improve Fuel Efficiency in Commercial Trucks

Key Parameters of Turbochargers for Construction Machinery Explained